ARDEX R40E is a solvent-free, 100% solids, high build epoxy paint that creates a tough, easy to clean surface in industrial environments or wherever high chemical and wear resistance is required. Applicable in workshops, production and processing areas, dairies, soft drink and bottling factories, breweries, kitchens and on any floor where wet work or chemical spillage is expected. In combination with 0.6 mm quartz sand ARDEX R40E can be used to produce multi-layered, high mechanical strength floorings from 2 to 4 mm thick.

- VOC free.

- High physical and chemical resistance.

- Excellent adhesion.

- Mixed with different types of aggregates, it can be used to produce floor coverings of various thicknesses.

- Resistant to a large number of chemical products.

- Easy to clean.

- Solvent-free.

- Possibility of multiple finishes (smooth, non-slip,...).

- Easy to apply.

Technical data

- Appearance: Viscous liquid

- Density: Approx. 1.4 g/cm3

- Pot-Life: >40 min

- Time between coats: Min. 15 hours

- Light traffic: 24 hours

- Total cure: 7 days

- Application: Rubber lip, medium/short nap roller.

- Adhesion: >3 N/mm2

- Consumption: 500-1000 gr/m2(per coat)

- Mixing ratio (by weight) 83 A : 17 B

- Packaging: Packs of 10/25 Kg A+B

Preparation of the substrate:

The substrate must be hard, solid and free of dust or other loose particles such as paint, remains of lime, mortar, plaster, adhesive residues, etc., which may impair adhesion to the substrate.

Before mechanical preparation, varnish, wax, grease, oil and similar contaminants must be removed. Contaminated concrete surfaces must be treated mechanically, either by sanding, shot blasting or sandblasting, followed by vacuuming.

Any joints or cracks in the concrete substrate where differential movement is expected, e.g. expansion joints, should be raised to the finished surface and sealed appropriately.

The substrate must have a tensile strength greater than 1.5 N/mm2.

Priming:

Prior to the application of ARDEX R40E the substrates must be primed with ARDEX PRIMER E (consumption approx. 200-300 gr/m2 depending on the absorption of the substrate).

Instructions for use:

Mixing:

The individual components of ARDEX R40E must be stirred before mixing.

The hardening agent (component B) is added to the resin (component A) and stirred with a drill fitted with a stirrer at a slow speed (400 rpm) until a uniform consistency is obtained.

It is very important that the components are well mixed (this is achieved by stirring for at least 3 minutes). Some of the mixture can be reintroduced into the hardener container to collect any residues that may remain in the container. The mixture that has passed through the hardener container is reintroduced into the mixing container and stirred for a further 30 seconds. This mixing process ensures the consistency of the product and that any resin remaining in any of the containers reacts, facilitating subsequent waste management.

Once mixed ARDEX R40E will generate a large amount of heat if left in the mixing container causing an abrupt decrease in pot-life.

Application:

Paint:

Once components A and B have been mixed, the material is applied directly onto the primed substrate by short nap roller or brush.

Self-levelling:

Once components A and B have been mixed, approximately 500 grams of 0.3-0.4 mm quartz sand is added per kilo of mixture. The material is poured onto the substrate and spread with a notched trowel so that the thickness can be controlled. A spiked roller should be passed immediately to facilitate the release of the air trapped under the coating, until the bubbles are completely eliminated. Approximately 2.0 kg/m2 of ARDEX R40E is required to achieve a thickness of 1 mm.

Multi-coat:

Once mixed ARDEX R40E should be spread over the floor without delay using a rubber lip, finishing the application (to remove imperfections) with a short nap roller. If sand is added to the mixture, this should be done with an ARDEX R40E: quartz sand ratio of 1:0.5.

The still wet ARDEX R40E layer is then sanded to saturation with 0.6 mm quartz aggregate.

The next day the sanded surface is swept and vacuumed to remove the unbonded aggregate.

The second coat of ARDEX R40E encapsulates the aggregate. This operation can be repeated as many times as necessary until the desired thickness is achieved.

Limitations:

These products cannot be applied at temperatures below 10ºC or above 30ºC or when the ambient humidity exceeds 85%.

If the pot-life is exceeded, the mixed product loses its characteristics and must be discarded.

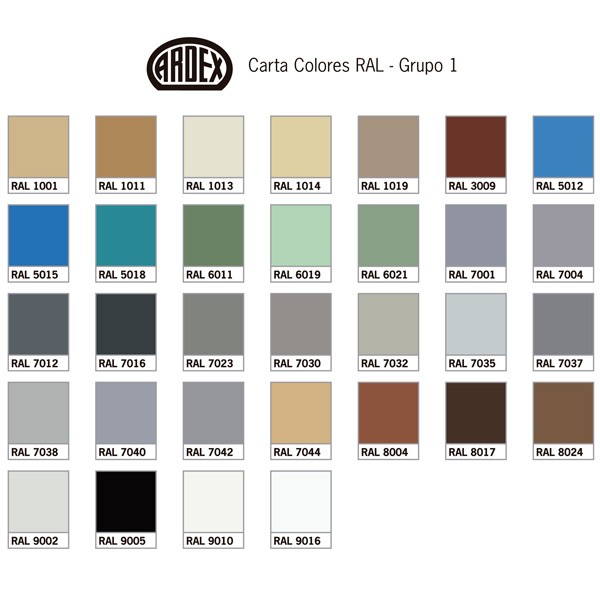

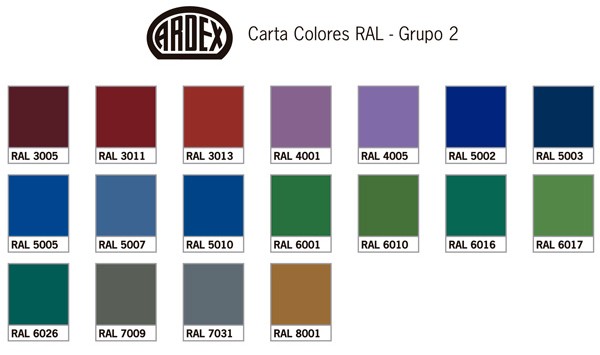

All ARDEX products are manufactured under strict quality controls and procedures, however, when colour consistency is essential, it is recommended that the products used are from the same batch.

Tool cleaning:

ARDEX R40E can be cleaned from tools and equipment immediately after use using a solvent such as ARDEX RTC cleaning solvent. In case the product hardens it can only be removed by mechanical means.

Residues/Spills:

Spillage of any of the products must be immediately scooped up with sand, vermiculite or other inert material and deposited in a suitable container for disposal.

Waste management of these spills and empty containers should be carried out in accordance with local legislation.

For further information refer to the safety data sheet.

Storage:

The shelf life of ARDEX R40E is 12 months, in the original closed containers.

Storage should be in a dry place between +5ºC and +30ºC. Protection from frost and direct sunlight and heat sources is required.

Precautions:

ARDEX R40E must not come into contact with eyes or skin and must not be ingested.

The hardener contains isophoron diamine and benzyl alcohol and the epoxy resin containing bisphenol A/F-epichlorhydrin, may irritate eyes and skin and may cause contact sensitisation. They are considered harmful in contact with the feet, eyes or if swallowed.

The following precautions should be observed during mixing or application: ensure adequate ventilation and avoid contact of the material with eyes, nostrils, mouth or skin. Avoid contact with hands, protecting them with gloves and protective cream if necessary. In case of contact with eyes, rinse immediately with plenty of water and seek medical advice. In case of contact with skin, wash immediately with soap and water (do not use solvents). Avoid prolonged skin contact, especially those with allergic reactions to epoxy materials. Always wear gloves and eye protection, if necessary. Take care of personal hygiene after work, or during breaks in work, by always washing hands. Take care when removing gloves not to contaminate the inside of the gloves.

When working in confined areas wear suitable respiratory equipment.

In case of accidental ingestion of product, seek immediate medical attention, do not induce vomiting.

In case of accident, seek medical advice. For further information see safety data sheet.